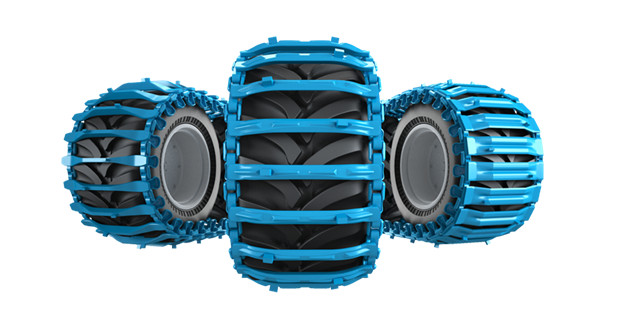

Market leading product development

Olofsfors philosophy and one of the main reasons for our existence is to develop products based on a great knowledge of the customers' conditions. Year after year, we continue to deliver innovative products that raise the bar for the entire industry. This belief in development and the commitment we feel towards our customers will lead us into promising future ventures.

About Olofsfors

For 260 years, Olofsfors has been manufacturing steel products of the highest quality. Today in the form of tracks for forestry machines and wear steel to the construction industry.

Read moreQuality and sustainability

Olofsfors is constantly working to find solutions to reduce our impact on the environment and develop our processes to ensure high quality.

Read moreSupport and service

We strive to provide the best and fastest support and service on the market to reduce your down-time and increase your profitability.

Read moreNews

The latest news from Olofsfors. About the company, products, investments, and our collaborations.

Olofsfors AB - Main office

Phone: +46 (0) 930-396 00

E-mail: info@olofsfors.se

Address: Olofsfors AB - Main office

Olofsfors 11

SE-914 91 Nordmaling, SE